Helpline: 99713-10122

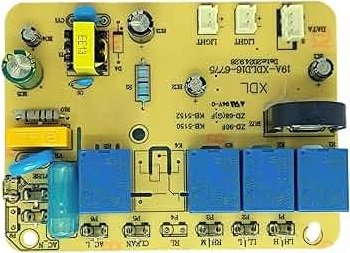

Chimney PCB Board

Spare Details

-

Spare Type:

Stainless Steel (SS) Baffle Filters, Metal Baffle Filters, 3-Layer Baffle Filters

-

Specification:

Input Voltage: 230V AC at 50Hz, Operating Voltage (DC): 5V, 12V, or 24V, Load Capacity: 150W to 250W, Control Channels:2-speed or 3-speed settings

The Digital Brain: A Comprehensive Guide to Chimney PCB Boards in India

In the modern Indian kitchen, the transition from traditional exhaust fans to smart, sleek chimneys has been driven by one core component: the Chimney PCB Board. PCB stands for Printed Circuit Board, and it serves as the "brain" of the appliance. Whether you are using a gesture-control chimney in Bengaluru or a touch-panel model in Delhi, the PCB is responsible for translating your commands into action. In the context of India, where cooking involves high heat, heavy steam, and frequent power fluctuations, the quality and specification of the PCB board are paramount for the appliance's longevity. We also deal in other home appliance spare parts like Chimneys, Hobs, RO systems, ACs, Fridges, Washing Machines, Microwaves, Dishwashers, Geysers, Coolers etc.

What is a Chimney PCB Board?

The chimney PCB is a complex board of copper tracks, resistors, capacitors, and microprocessors mounted on an insulating substrate. Its primary role is to control the power supply to the motor, manage the lighting system, and process inputs from the user interface (buttons, touch sensors, or motion sensors). In an India home, the PCB also acts as a safety regulator, ensuring that the motor does not overheat during a prolonged deep-frying session.

Technical Specifications for the Indian Market

When choosing a chimney or looking for a replacement PCB in India from brands like Faber, Elica, or Hindware, you must consider these technical parameters:

-

Input Voltage: Designed for the standard Indian power grid of 230V AC at 50Hz.

-

Operating Voltage (DC): Most PCBs convert the high-voltage AC to low-voltage DC (typically 5V, 12V, or 24V) to power the sensitive microchips and LED lights.

-

Load Capacity: The PCB must be rated to handle the wattage of the chimney motor, which in India typically ranges from 150W to 250W.

-

Control Channels: A standard PCB manages multiple speeds (usually 2-speed or 3-speed settings) and a separate channel for the light.

-

Thermal Tolerance: High-quality boards in India are coated with a protective "Conformal Coating." This is a vital specification as it protects the circuits from the high humidity of Mumbai and the grease-laden air typical of Indian cooking.

Types of Chimney PCB Boards in India

The complexity of the PCB varies based on the features of the chimney:

1. Mechanical/Push-Button PCB

Found in budget-friendly chimneys across India. These are relatively simple boards that use physical switches to complete the circuit. They are robust and highly resistant to voltage spikes common in rural areas or older neighborhoods in Kolkata.

2. Touch Control PCB

Popular in modern apartments in Hyderabad or Pune. These boards feature capacitive touch sensors. They are sleek and easy to clean because they sit behind a glass panel, preventing grease from entering the switches.

3. Gesture Control PCB

The latest trend in the India market. These PCBs are equipped with infrared (IR) sensors that detect hand movements. This allows you to turn the chimney on or adjust speeds without touching the unit with oily hands, keeping the glass surface pristine.

4. Auto-Clean Control PCB

Specific to "Heat Auto-Clean" chimneys. This board includes a timer and a relay that powers a heating element around the motor housing for a set duration (usually 10 to 15 minutes) to melt trapped oil.

Maintenance and Troubleshooting in India

The most common enemy of the chimney PCB in India is the combination of moisture and oily soot. Over time, these can create "carbon tracks" on the board, leading to short circuits. In coastal cities like Chennai, salt in the air can also lead to corrosion. It is highly recommended to use a Voltage Stabilizer for your chimney if you live in an area with unstable power, as a single high-voltage surge can fry the delicate microprocessors on the PCB.

Frequently Asked Questions (FAQ)

Can I repair a burnt chimney PCB board? In many cases in India, a local technician can replace a blown capacitor or a burnt fuse on the board. However, if the main microprocessor is damaged, the entire PCB must be replaced.

Why is my chimney starting on its own? In the humid climate of India, moisture can get trapped behind the touch panel, causing the PCB to register "ghost touches." Cleaning the panel with a dry cloth or using a hairdryer on a low setting to remove moisture often helps.

Are chimney PCBs interchangeable between brands like Elica and Faber? No. Every brand uses a unique pin configuration and software logic. Even within a brand like Hindware, the PCB for a 60cm model might differ from a 90cm model. Always use the specific part number for your unit.

What is the cost of a replacement PCB in India? Depending on the technology (Touch vs. Gesture), a new PCB can cost anywhere between ₹1,200 and ₹4,500. Always purchase from authorized service centers to ensure you get a genuine part with a warranty.

Does the "Auto-Clean" feature have a separate PCB? Usually, the auto-clean logic is integrated into the main PCB. However, some high-end chimneys in India use a "Dual-Board" system where the power logic and the user-interface logic are on separate boards.

Would you like me to help you find the circuit diagram or a replacement PCB for your specific chimney brand in India?

SparesMedia (store manager) –

The circuit board replacement was plug-and-play for my touch-control model. Much cheaper than a new unit