Helpline: 99713-10122

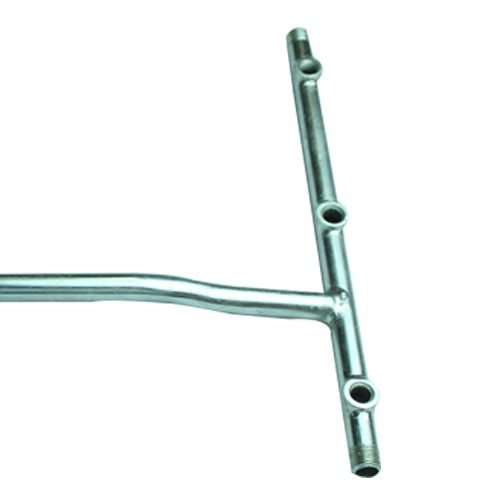

Hob MS Pipe

Spare Details

-

Spare Type:

Linear Manifold Pipes, U-Shaped or Square Manifolds, High-Flow MS Pipes

-

Specification:

Material:Cold Rolled Mild Steel, Coating and Protection: Electroplated with zinc,Wall Thickness: 1.5mm to 2.5mm, Joint Integrity: Orbital Welded

The Structural Backbone: A Comprehensive Guide to Hob MS Pipes in India

In the modern India kitchen, the built-in hob has revolutionized cooking with its sleek profile and high-efficiency burners. While we often admire the glass top or the metallic knobs, the safety and performance of the appliance are governed by the internal plumbing. The Hob MS Pipe (Mild Steel Pipe) is the critical conduit that transports gas from the main inlet to the individual burners. In a country like India, where cooking involves high heat and long hours, the quality and specification of this internal manifold are non-negotiable for kitchen safety. We also deal in other home appliance spare parts like Chimneys, Hobs, RO systems, ACs, Fridges, Washing Machines, Microwaves, Dishwashers, Geysers, Coolers etc.

What is a Hob MS Pipe?

The MS pipe, or manifold, is the internal rail system of a gas hob. It is constructed from Mild Steel, a material chosen for its excellent balance of strength, ductility, and ability to be welded into airtight configurations. In cities like Mumbai, Delhi, and Bengaluru, where gas hobs are used multiple times a day, this pipe must maintain a perfect seal under varying gas pressures to prevent hazardous leaks within the kitchen cabinetry.

Key Technical Specifications for the Indian Market

When evaluating a gas hob from brands like Faber, Elica, or Glen, the internal MS pipe must meet specific standards to ensure longevity in the Indian climate:

-

Material Grade: High-quality hobs in India use Cold Rolled Mild Steel. This grade ensures a smooth internal surface, which minimizes gas turbulence and prevents the accumulation of impurities found in some gas supplies.

-

Coating and Protection: Since the kitchen environment is humid, especially in coastal cities like Chennai or Kolkata, MS pipes are typically Powder Coated or Electroplated with zinc. This prevents rust and corrosion that could lead to "pinhole" leaks over time.

-

Wall Thickness: For domestic hobs in India, the pipe wall thickness generally ranges from 1.5mm to 2.5mm. A thicker pipe provides better structural integrity and can withstand higher pressures without deformation.

-

Joint Integrity: In a multi-burner hob, the MS pipe features "T-junctions" for each burner. These joints must be Orbital Welded or sealed with high-grade industrial adhesives to remain airtight for decades.

-

Pressure Rating: Most domestic hob MS pipes in India are tested to withstand pressures significantly higher than standard LPG or PNG supply, often up to 10 bars, ensuring a massive safety margin.

Types of Hob MS Pipes and Manifolds in India

1. Linear Manifold Pipes

The most common type found in 3-burner and 4-burner "straight" hobs in India. This is a single long pipe with outlets branching off at intervals. It is easy to service and provides uniform gas pressure to all burners.

2. U-Shaped or Square Manifolds

Used in compact or square-shaped hobs often installed in smaller apartments in Pune or Hyderabad. The pipe is bent into a specific shape to fit the tight chassis while ensuring the gas path remains unobstructed.

3. High-Flow MS Pipes

Specifically designed for hobs with "Triple Ring" or "Wok" burners common in India. These pipes have a larger internal diameter to accommodate the higher volume of gas required for intense "Tadka" cooking.

Maintenance and Safety in the Indian Kitchen

In India, gas leaks are a significant concern. Because the MS pipe is hidden under the glass or steel top of the hob, a leak can go unnoticed for a long time. It is vital for homeowners in Gurugram or Ahmedabad to ensure that their hob is installed by a certified professional. Over time, the rubber O-rings that connect the MS pipe to the aluminum gas valves can perish. A periodic "Soap Bubble Test" around these internal joints during annual maintenance is a standard safety practice in India.

Frequently Asked Questions (FAQ)

Why is Mild Steel used for hob pipes instead of Copper? While copper is excellent, Mild Steel provides superior structural strength and is less likely to bend or kink during the heavy usage and cleaning routines common in India. It is also more cost-effective for large-scale appliance manufacturing.

How do I know if my Hob MS Pipe is leaking? If you smell gas even when the knobs are off, or if you hear a faint "hissing" sound coming from inside the hob in your India kitchen, it indicates a leak in the MS pipe or its connections. Turn off the main gas valve immediately.

Can rust affect the internal MS pipe? Yes. In coastal cities like Kochi or Mumbai, humidity can cause untreated mild steel to rust. This is why you should always buy hobs from reputable brands in India that use powder-coated or galvanized MS pipes.

Are the internal pipes of LPG and PNG hobs different? The MS pipe itself is usually the same. However, the nozzles attached to the pipe are different. In India, if you switch from LPG to PNG, you change the injectors, but the main MS manifold remains the same.

What is the lifespan of an MS pipe in a kitchen hob? With proper coating and professional installation, a high-quality MS pipe in an India home can last 10 to 15 years without any issues.

Would you like me to provide a list of top-rated hob models in India that feature reinforced and anti-corrosive MS pipe manifolds?

SparesMedia (store manager) –

Previous Ms pipe had leakage issue. This pipe is perfect for my hob. No issue now.